Ukuqoshwa kwama-laser, ukuhlanza, ukushiswa kwemishini kanye nemishini yokumaka

Thola isilinganiso

Imikhiqizo

Umshini wokumaka we-fiber we-laser wensimbi

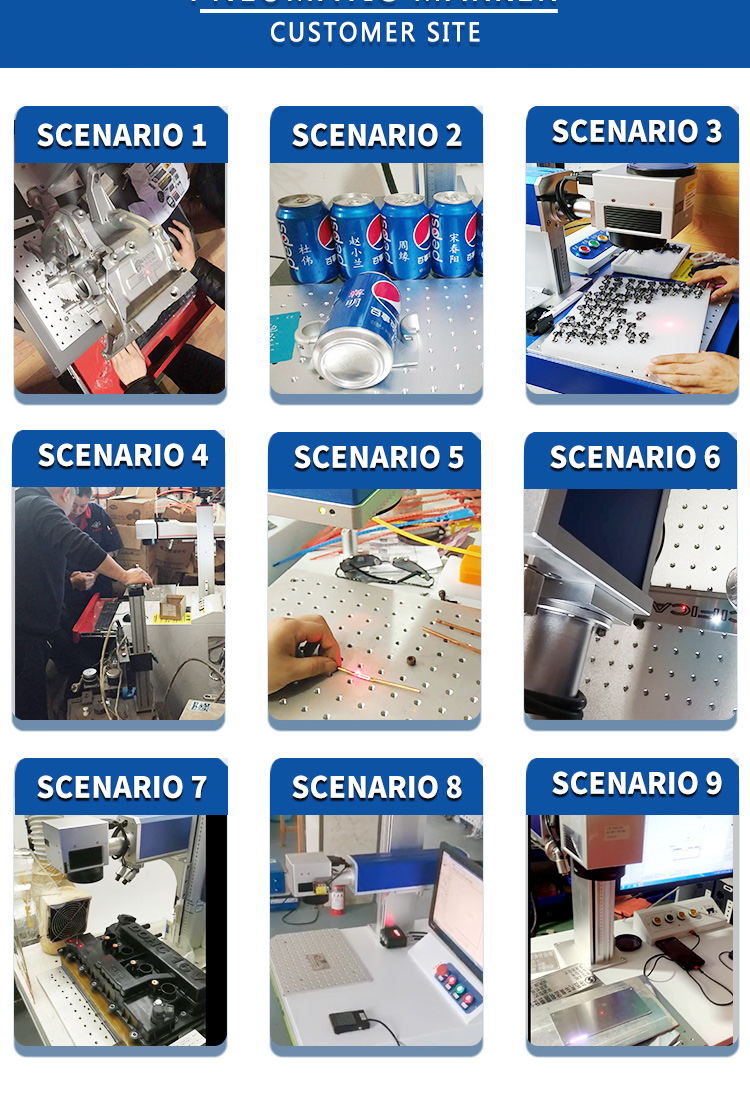

Njengoba ukukhiqiza kuthuthuka ngokwengeziwe, amabhizinisi ayaqhubeka nokufuna izindlela ezisheshayo nezisebenza kahle zokumaka imikhiqizo. Indlela ephumelela kakhulu ukusebenzisa umshini wokumaka we-laser we-fiber laser eyenzelwe izinto zensimbi.

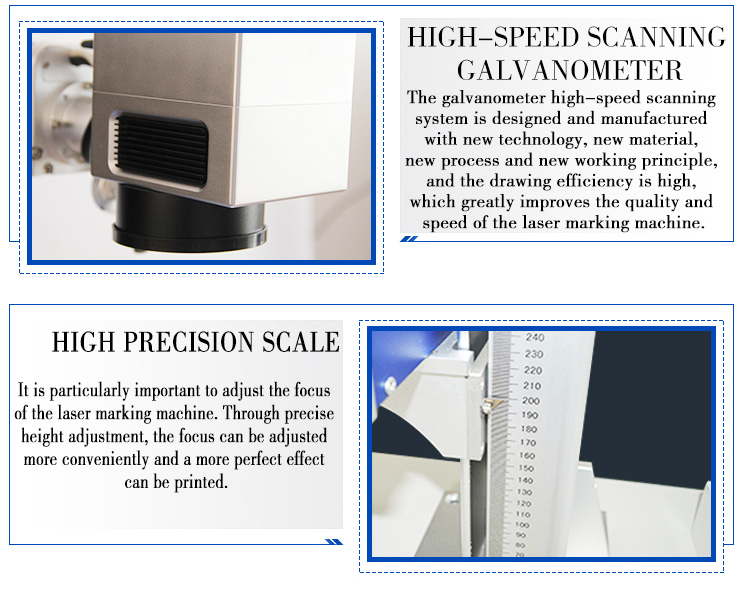

Ngokungafani nezindlela zokumaka zendabuko njengokuqopha, ukugxila noma ukuphrinta, imishini ye-fiber laser isebenzisa ama-lasers aphezulu ukuze aguqule ingaphezulu kwezinto zensimbi ezimakwe. Le mishini inembe kangangokuba ingenza amamaki ayinkimbinkimbi futhi anemininingwane cishe kunoma yiluphi uhlobo lwensimbi, kufaka phakathi insimbi, i-aluminium, ithusi nethusi.

Imishini yokumaka ye-Gaber Laser yokumaka isebenzisa ukukhanya okuhlanganisiwe kokukhanya ukudala umaki osezingeni eliphakeme ezindaweni zensimbi ezihlala njalo futhi ezihlala isikhathi eside. Ubuchwepheshe bunembe kakhulu kangangokuba akukho ndawo yephutha, okwenza kube yisinqumo esithandwayo ezimbonini ezihlukene njengokwenziwa kobucwebecwebe, i-aerospe, ezenzakalelayo nezokwelapha ezokukhiqiza amadivayisi.

I-Fibre Lasers ingakhiqiza amamaki wokujula okuhlukahlukene nobubanzi, ngokuya ngokusetha okusetshenzisiwe, futhi kungakhiqiza amamaki amancane amancane njengama-microns ambalwa. Ngokwengeziwe, imishini ye-fiber laser ingasetshenziswa ukumaka ama-logo, izinombolo ze-serial, amakhodi webha nezinye izinhlobo zemibhalo namahluzo.

Enye yezinzuzo zokusebenzisa umshini wokumaka wensimbi we-laser we-laser ukushesha kanye nokusebenza kahle kwenqubo. Ukumaka kwe-laser kusheshe futhi kukhiqize imiphumela engaguquki kunezindlela zokumaka zendabuko. Ngokuhamba kwesikhathi, lokhu kungaholela ekukhiqizweni okwengeziwe kanye nokonga izindleko ezibalulekile.

Enye inzuzo yokusebenzisa umshini wokumaka we-fiber laser ukuthi amamaki anembile kakhulu futhi aqinile. Le mishini ikhiqiza ukumaka okuseqophelweni eliphezulu okumelana ne-abrasion, ukugqwala kanye nemisebe ye-UV. Futhi mancane amathuba okuphela, ibala noma ekuqaleni, okwenza balungele izinhlelo zokusebenza ezidinga ukuqina.