Ukuqoshwa kwama-laser, ukuhlanza, ukushiswa kwemishini kanye nemishini yokumaka

Thola isilinganiso

Imikhiqizo

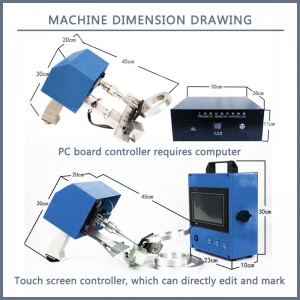

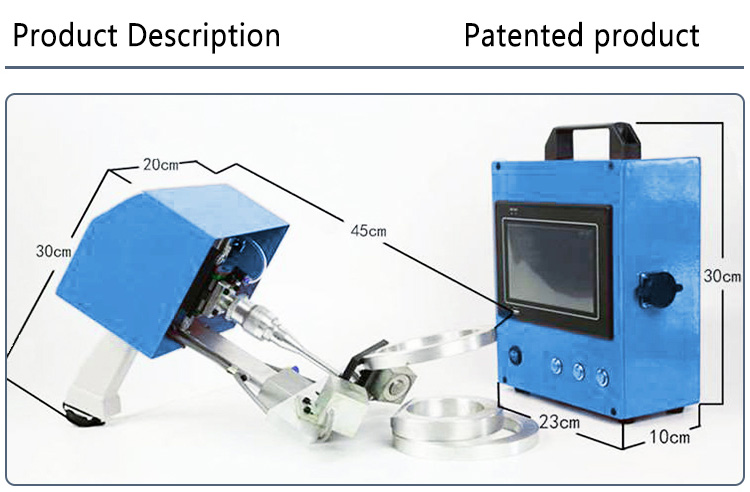

Umshini wokumaka isilinda sensimbi

Ukufanisa

Imishini yokumaka ama-pneumatic ngamathuluzi aguquguqukayo angasetshenziselwa ukumaka izinto ezahlukahlukene, kufaka phakathi insimbi, ipulasitiki, ngokhuni nesikhumba.

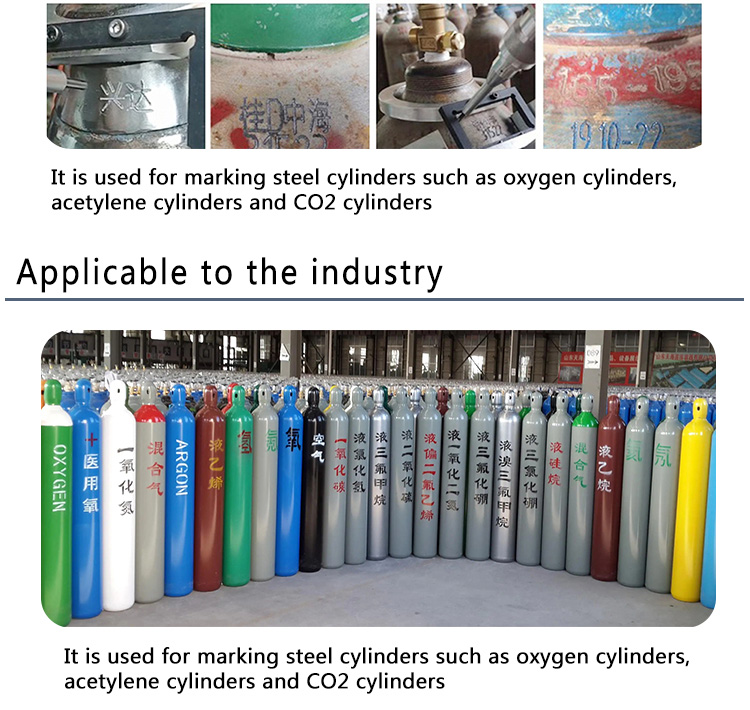

Uhlobo olulodwa lomshini wokumaka we-pneumatic othole ukuthandwa eminyakeni yamuva nje umshini wokumaka we-pneumatic wensimbi.

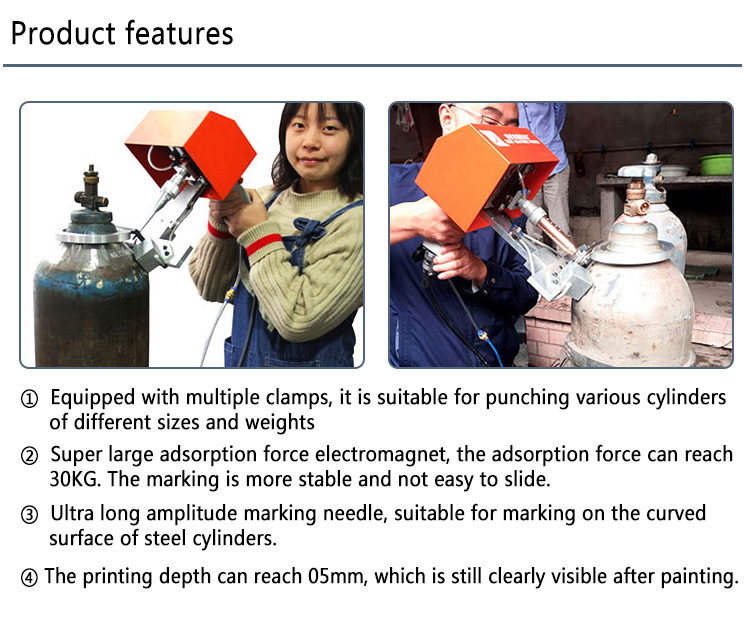

Lolu hlobo lomshini wokumaka lwenzelwe ngqo ukumaka amabhodlela ensimbi noma amasilinda. Ifaka ukuhlanganiswa okukhethekile okubambe ibhodlela lensimbi endaweni futhi kuvumela ukumake okungama-360-degree.

Idizayini yokumaka eyindilinga ilusizo ikakhulukazi kuma-logo noma izimpawu ezindaweni zokulinda, ezinjenge-cylinders kaphethiloli noma izicishamlilo.

Enye yezinzuzo zokusebenzisa umshini wokumaka we-pneumatic yijubane lapho kungakhiqiza khona ukumaka okucacile, okubonakalayo. Umshini wokumaka we-bwoodle we-steel ungamaka izinhlamvu ezingama-40 ngomzuzwana, uhlinzeka ngesisombululo esisheshayo nesisebenzayo sokumaka sabakhiqizi kanye nezinye izinhlelo zokusebenza zezimboni.

Enye inzuzo yomshini wokumaka we-steel-ibhodlela we-pneumatic ukulula ukusetshenziswa kwayo. Umshini usetshenziswa ngokusebenzisa isikhombimsebenzisi esilula esingakwazi kahle ngokushesha ngabasebenza kuwo wonke amazinga amakhono.

Ngokwengeziwe, ukulungiswa komshini nezilungiselelo zomshini kungashintshwa kalula ukuze kuhlaliswe osayizi abahlukahlukene bebhodlela kanye nezidingo zokumaka.

Ngokufingqwa, umshini wensimbi webhodlela le-pneumatic makering iyithuluzi elithembekile nelisebenzayo lokumaka amabhodlela ensimbi ye-cylindrical.

Idizayini yayo yokumaka eyindilinga kanye nesivinini sokumaka ngokushesha kwenza kube ukukhetha okuthandwa ngabakhiqizi kanye nezinye izinhlelo zokusebenza zezimboni. Futhi, ngesibonisi sayo esisebenziseka kalula nezilungiselelo eziguqukayo, lo mshini utholakala kubasebenzi bawo wonke amazinga amakhono.